| About Echo Tech Design |

| About 44 West Construction |

| Project | The Tim Palen Studio at Shadow Mountain |

| Design | Walter Scott Perry, Echo Tech Design |

| Contractor | Eric Engheben, 44 West Construction |

| Containers | 6 |

| Location | Joshua Tree, California, USA |

| Year | 2010 |

| Photography | Jack Parsons |

The modular shipping container home is composed of diverse steel elements, including: 6 repurposed containers, a 10,000 gallon water tank, a Butler pre-engineered building, and a steel shade canopy with integrated metal framing system that provides wind, fire and earthquake protection, extraordinary strength, as well as large door and window openings to maximize cooling, ventilation, and natural daylighting. An adjustable, bolt-on shade and steel frame system creates wind, glare and 50% solar heat reduction on the house; solar breezeway creates suitable location for plug-in attachment of future water heating panel and solar electric arrays.

By combining mass-produced and high-efficiency modular construction methods with contemporary innovative design in one of the most harsh climate zones in United States, designers have developed a sustainable and low-cost housing system that can be delivered and quickly assembled anywhere in the world.

Description from architects

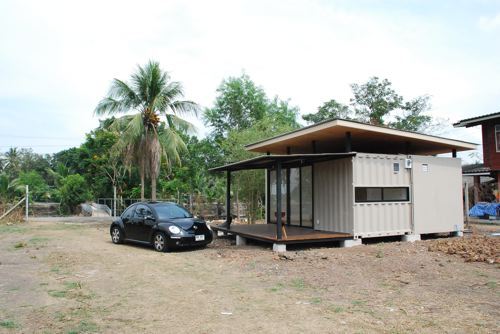

A prototype hybrid house, also known as the Tim Palen Studio at Shadow Mountain is the first repurposed container home permitted and built in the Mojave Desert. Based on the fuel-efficient Prius automobile engineering concept, the residence combines the energy and production efficiencies of diverse pre-engineered building and energy systems working together seamlessly to produce a smooth-running hybrid green machine for living.

The residence is a prototype of 2nd generation pre-fab design and a kit-like housing product developed by ecotechbuild, the design-build subsidiary of ecotechdesign. It is constructed from 5-20′ long recycled cargo containers that were fabricated and finished in Los Angeles and then shipped to the site where they were erected and stacked 2 high in 15 minutes each. All site work, including foundations and utility placement was constructed at the remote desert site during container fabrication in Los Angeles.

The residence is the 1 bedroom, 1-1/2 bath, 2 story model hybridhouse_1 design that has been adapted for a media client who required a separate photo studio and storage building. The studio is constructed of a Butler pre-engineered steel building with plug-in cargo container storage. It is naturally daylite with 22″ dia. Solutubes, which can be manually controlled and temperature balanced using efficient, dimmable strip lighting.

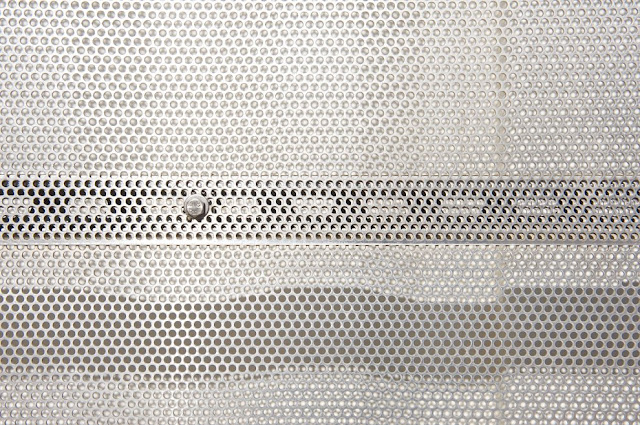

The container residence and the pre-engineered, steel studio structure act as two bookends that support framing and, in turn a perforated metal shade canopy that wraps the container’s roof, south-facing steel walls and the dramatic 20′ high outside living space, aka solar breezeway to provide protection against desert heat, glare, wind and blowing sand. The breezeway, in turn moderates and then directs a flow of air through the container spaces to enhance passive cooling. A naturally lit, steel-clad stair structure connects the 2 level stacked containers and doubles as a 20′ story high photo gallery in which to display artwork.

Other features include:

- Hybrid House Design: based on the efficient Prius engineering concept, the hybrid house concept combines diverse, pre-engineered building and energy conservation features to maximize efficiency and cost savings, while offering architectural design flexibility and variation.

- All Recycled Steel Construction: the project is composed of diverse components, including: (6) repurposed ISO cargo containers, a Butler pre-engineered building, a 10,000 gal. storage tank, at solar shade canopy and an integrated steel framing system that provides extraordinary strength, earthquake, fire and wind protections, as well as large window and door openings to maximize natural daylighting, ventilation and cooling.

- Solar Home Shading System: a bolt-on, adjustable steel frame and perforated metal shade system creates 50% solar heat, glare and wind reduction on the building and solar breezeway and allows for the plug-in attachment of future solar electric and water heating panel arrays.

- Living Roof System: movable, bolt and add-on modules use greywater irrigation and are planted with native desert plants and sedums to absorb heat, glare, dust and CO2.

- Water Conservation: integrated greywater for irrigation, water harvesting and storage systems.

- Energy Conservation: an innovative steel framework allows for the placement of a “cool roof” and insulation system and a triple wall insulation system combine to create a building envelope that exceeds California energy code requirements by 50%. All appliances, fixtures and heating systems are Energy Star rated.

- Reduced Costs: Finished construction costs, including footings and sitework was $150/SF, far below construction costs for comparable prefab home or manufactured home construction.

About Echo Tech Design

Ecotechdesign under the inspired leadership of architect, Walter Scott Perry has been involved in green, currently referred to as sustainable thinking and design for over 40 years, having been a leader and pioneer in the passive solar design movement incubated in Santa Fe, NM and birthed by the oil embargo crisis of 1972.

Our collaborative approach has been developed over many years in order to seamlessly integrate design with construction and material systems research, as well as encourage professional and political participation to solve problems more quickly and effectively.

Ecotechdesign pioneered the green team design approach during the 1990’s.

The 4 subgroups are: ecotechdesign, ecotechbuild, ecotechr+d, ecotech consult.

The practice is a diverse and full-service design collaborative that examines and explores practical ways to integrate client needs, project cost limitations, physical construction, energy conservation opportunities and innovation with local climate and living systems in a timely and responsive way. It embraces the philosophy that all things are inter-connected and merely exist at different levels of perception and reality, some large and some small, some visible and some hard to see. Embracing a whole systems thinking approach to problem solving, it explores patterns at all scales from macro to micro to explore and develop ways to integrate natural and man-made materials and systems. The design process is a problem-solving approach that considers design, engineering and space-making as an organic process of investigation, discovery and collaboration. This results in a practical and functional, yet aesthetically balanced and responsive, organic architecture.

Using a building kit approach that utilizes plug-in components, ecotechdesign incorporates a hybrid design approach. Like the Prius hybrid automobile design, it combines different building technologies and energy systems to maximize energy, spatial and cost efficiencies that result in practical solutions while achieving substantial architectural variety and flexibility. Ecotechdesign explores the use of conventional building systems and materials combined with innovative solutions developed by its subgroup ecotechr+d that investigates new ways of combining old materials to solve new problems. Solarshade which was used to cool hybridhouse is a good example of the innovative use of low-cost and readily available materials and systems to passively cool a building.

| Address | Walter Scott Perry, Architect 8834 Hollywood Hills Road, Los Angeles, CA 90046, USA | |

| Phone | +1 323-650-2827 | |

| +1 323-270-5502 | ||

| ecotech@sbcglobal.net | ||

| Website | https://ecotechdesign.com/ |

About 44 West Construction

The Building Process

- Design and Ideas

- Architect - Engineering - Plans

- City and state approvals, plan check, coastal commission if applicable.

- Bidding with qualified contractors.

- Sign a contract with a contractor.

- If hazardous waste is encountered anywhere on a site, it must be addressed and abated before any work can begin. A notification must be sent to AQMD (Air Quality Management District). A ten day waiting period before construction or demolition can begin may apply. Check with your contractor.

- Pre-construction meeting with city grading official if applicable.

- Construction start, work on site.

- Site preparation begins

- The land is cleared and any existing structures are demolished.

- City and engineer inspections are completed prior to pouring concrete.

- The foundation concrete is formed and poured.

- Framing of the structure and placement of steel.

- Installation of windows and exterior door frames.

- Electric, plumbing and mechanical rough-in installations.

- Framing, electric, plumbing and mechanical inspections by the city and engineer.

- Roofing, which may be a multiple step process depending on the roof style.

- Stucco paper and wire wrap or the start of exterior siding.

- City inspection of paper and wire installations if stucco is used.

- Insulation

- Interior wall finishes, drywall, plaster etc.

- Interior woodwork and cabinets.

- Tile and hard surfaces.

- Painting.

- Flooring.

- Landscaping.

This process is a general guideline for most residential projects. Commercial projects and remodels may follow a different process, although this one has worked well for our business for many years.

| Address | 274 Muerdago Rd, Topanga, CA 90290, United States | |

| Phone | +1 310-455-2517 | |

| Fax | +1 310-455-2587 | |

| build@44west.net | ||

| Website | http://www.44west.net/html/index.html |

More shipping container homes in California:

McConkey Shipping Container Home, San Diego, California

Beautiful Shipping Container House Concept by Whitaker Studio, California

Low Cost Shipping Container Office Space, Los Angeles, California

Two-Story 4x40ft and 1x20ft Shipping Container Home, Santa Barbara, California

20 ft shipping container home in Sacramento, California

Shipping Container Duplex House, Redondo Beach, California

Shipping containers in loft apartment, San Francisco, California

Refrigerated Shipping Container Home, San Francisco, California

192 sq ft Shipping Container Guest Cabin, San Francisco, California

Modular Shipping Container Home in Mojave Desert, California